What Construction KPIs Can Be Measured Using Satellite and Drone Data?

Part 3 in our EO Hub construction series

In the evolving landscape of the construction industry, drones have already proven invaluable, and satellite technologies look set to join them, especially for large-scale and mega-projects. Used in tandem, these tools have the potential to transform the sector, capturing precision details, providing a high-level view of project progression, and ushering in a new era of data-driven decision making.

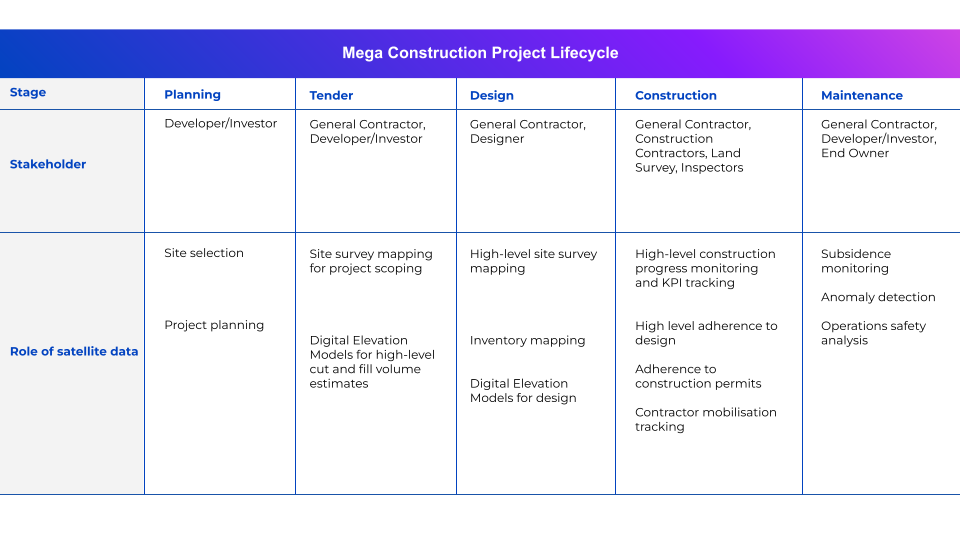

We’ve previously explored the different roles of satellite and drone data in construction progress monitoring and the value satellite data can add for different stakeholders. In the third and final article in our series, we explore the specific roles each of these technologies can play in measuring vital key performance indicators (KPIs), and precisely what KPIs they are able to capture.

Construction KPIs: Key functions of Earth Observation

For construction mega projects, different stakeholders will naturally be interested in different sets of KPIs. While general contractors, construction companies, designers, inspectors and land surveyors will be interested in engineering analysis of every centimeter of the construction, investors and owners will be interested in a more high-level view of the site—very challenging over the vast expanse of a mega project.

In this context, drones and satellites carve out separate but complementary niches in the construction industry, each offering unique insights. Furthermore, these tools are most effective when used in combination with traditional methods, such as in-person land surveying. Used as part of a holistic approach to construction monitoring, Earth Observation tools have the potential to support many different aspects of a project:

Schedule Adherence: One of the hallmarks of a successful project is its ability to stick to timelines. Both drones and satellites can help to monitor the rate of on-site completion. Satellite data will be used to detect high level adherence to work schedule, such as whether the mobilization of resources, equipment, and machinery is going according to plan, or whether the construction of particular structures are on time. Drone data will allow stakeholders to go a little deeper, looking at specific steps for each structure—if the footing is ready, reinforcement installed, support pillars in place, etc.

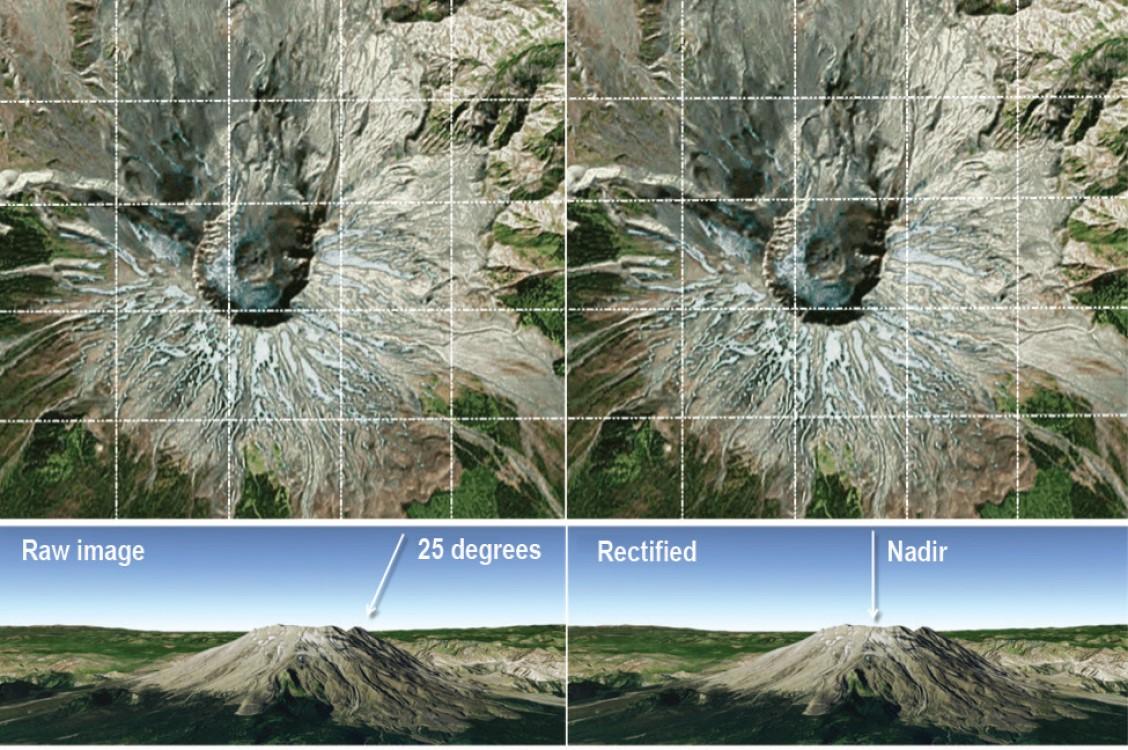

Budget Management: Both technologies aid in cost control by tracking resource allocation; for example, monitoring the volume of materials being used at different project phases, and by spotting any discrepancies that may hint at possible issues with wastage or theft. Drones are already a standard tool used for volumetric measurements of construction earthworks, proving much more accurate than traditional methods. Satellite data products such as Elevation 0.5 from Airbus allow measurement of 50cm volumes; this may not be accurate enough to provide detailed measurements, but it can give a high-level overview of resources on site.

Quality Control: In terms of quality control, detailed drone imagery is ideal for spotting minute structural inconsistencies or deviations from design specifications. Optical and LiDAR sensor–equipped drones provide absolute accuracy down to the level of several centimeters, which cannot fully substitute traditional high-precision methods, but is more than enough for many engineering KPIs. Satellite imagery, on the other hand, is often the only tool which can detect any changes over the broader area (e.g. surface deformation or environmental factors) which might compromise the project’s quality.

Safety Compliance: On a construction site, safety is paramount. Here, drones can be tasked to spot specific safety lapses, such as improper material storage, the absence of safety gear, or unsafe working conditions. Satellites can measure large-scale hazards such as pooling water, potential landslides, or emissions.

Environmental Impact: Satellites are the best tool for monitoring environmental KPIs. They are unsurpassed when it comes to measuring broad changes in local ecosystems, such as alterations in local vegetation patterns or bodies of water, or even changing wildlife activity. All these factors provide insights into a project’s environmental impact. Satellites are also able to track a mega project’s alignment with any environmental standards and regulations.

Stakeholder Communication: Regular visual updates are invaluable for stakeholder engagement. Here, drone-captured imagery provides detailed insights into the project’s evolution and information about specific structures, while comprehensive satellite images provide a full view over the whole mega-project site, allowing stakeholders to follow the project’s progression in its entirety.

Productivity Metrics: Specific KPIs and units of measurement

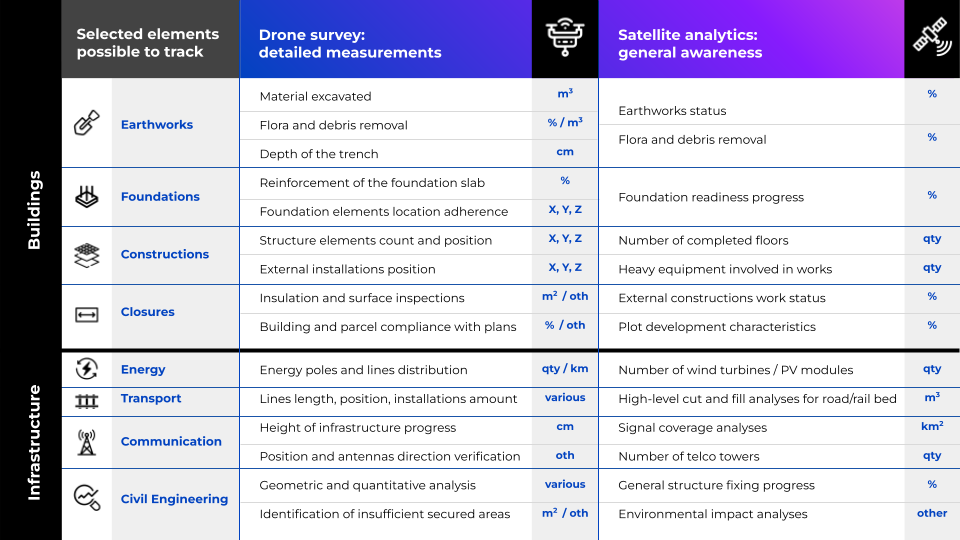

Having touched on the overarching roles of drones and satellites, it’s worth digging deeper into some specific KPIs and their units of measurement to help understand the contribution of drones and satellites when it comes to tracking progress. Drones are primarily an engineering tool, while satellites function as a management tool, and the specific KPIs reflect this. However, both tools can play a role in gauging productivity by capturing specific measurements for accuracy and consistency, with drones quantifying on-the-ground activity like worker numbers or equipment use, and satellites assessing the overall pace and scale of the project.

For instance, when monitoring earthworks, drones can capture trench depths to a centimeter level, and calculate the volume of excavated material in cubic meters. Satellites, on the other hand, provide a high-level overview of factors that affect the whole project, like the amount of vegetation displaced or percentage of earthworks completed. While foundations are being laid, drones are able to verify the placement of elements using specific geographic coordinates. Satellites offer a broader view, measuring foundation readiness, and a high-level view whether concrete has been poured or not.

During construction, drones track the exact positioning of structural elements, while satellites can, for example, detect the presence of heavy machinery by count, indicating the scale of work in progress, and can measure the percent of completed structures. In the closures phase, drones may focus on issues like insulation and surface inspections, while satellites capture a macro view of external construction work progress, marking high-level milestones as they’re achieved.

Of course, different types of construction projects will require different types of KPIs to be measured. For instance, in infrastructure projects, drones measure specific details, such as the distribution of power lines or the height of structures in centimeters. Satellites count larger features, like the total number of turbines or pylons, and can provide high-level volume measurements, like cut-and-fill analysis in cubic meters. Within civil engineering, drones deliver detailed and quantitative geometric analyses, whereas satellites offer high-level insights assessments of construction progress and broader environmental impact assessments.

Earth observation in construction: a suite of tools for complete and holistic project oversight

Drones and satellites have undeniable potential to revolutionize the way we approach construction, particularly in large-scale projects. These technologies, when coupled with advanced analytics, offer an unparalleled depth of insight, allowing for meticulous tracking and improvement of vital construction metrics and KPIs. This holistic overview, combined with granular detail, grants managers an extraordinary level of control and oversight.

Throughout this series—describing the different roles of satellite and drone data in progress monitoring, showcasing their immense value for various stakeholders, and laying out their functions when it comes to KPIs—it’s hopefully become clear that the use of these technologies drives efficiency, refines quality, and significantly augments the chances of a project’s success.

As we conclude the series, we hope that the construction industry is ready to embrace these advancements, not just to keep mega-projects on track in terms of efficiencies, but to propel the entire sector into a more precise, informed, responsible and sustainable future.

Did you like the article? Read more and subscribe to our monthly newsletter!